Electric scooter motors are the engines that power electric scooters. These motors convert electrical energy into mechanical energy to propel the scooter forward. They come in various types and sizes, each with its unique features and characteristics. The purpose of an electric scooter motor is to provide the power needed to move the scooter. It serves as the driving force behind the e-scooter’s movement and allows the rider to control the speed and direction of the scooter. On the other hand, with the increasing demand for eco-friendly and efficient transportation options, electric scooters have become increasingly popular, making the electric scooter motor an important component in the design and functionality of these vehicles.

Electric Scooter Motors Explained

1. Brushless DC Motor (BLDC)

A Brushless DC Motor (BLDC) is a type of electric motor that utilizes a permanent magnet rotor and a stator with electronic commutation. Unlike traditional DC motors, which use brushes to transfer electrical energy to the rotor, BLDC motors have no physical contact between the rotor and stator.

It eliminates the need for regular maintenance and increases the lifespan of the motor. BLDC motors are commonly used in applications such as electric vehicles, drones, and household appliances.

Brushless DC Motor Pros

High Efficiency

BLDC motors have a high level of efficiency which means they can convert more of the electrical energy they consume into mechanical energy.

Long Lifespan

The lack of mechanical contact between the rotor and stator eliminates wear and tear, resulting in a longer lifespan for the motor.

Low Noise

BLDC motors produce less noise than traditional DC motors, making them ideal for applications where noise is a concern.

Smooth Operation

BLDC motors have a smooth and consistent operation which is beneficial for applications that require precise control.

Low Maintenance

BLDC motors have no mechanical parts that require regular maintenance, which reduces the cost of ownership.

Brushless DC Motor Cons

Complex Control

BLDC motors require sophisticated electronic controllers, which can be more complex and expensive than traditional DC motor controllers.

Higher Cost

BLDC motors can be more expensive than traditional DC motors, which may make them less cost-effective for certain applications.

Limited Power Density

BLDC motors may have a lower power density than traditional DC motors, which means they may be larger and heavier for a given power output.

Sensitive to External Conditions

BLDC motors are sensitive to external conditions such as temperature and humidity, which can affect their performance.

2. Permanent Magnet AC Motor (PMAC)

Permanent Magnet AC Motors (PMAC) is a popular choice for electric vehicles, such as electric cars and scooters, as they utilize permanent magnets to generate a magnetic field. Unlike traditional electromagnets, PMAC motors are designed to operate on alternating current (AC) power, allowing for a direct connection to the power grid without the need for a converter.

The rotor, which contains embedded permanent magnets, rotates within a stator made of wire windings. As AC power is applied to the stator, a rotating magnetic field is created, driving the rotation of the rotor and producing mechanical power.

Permanent Magnet AC Motor Pros

High Efficiency

PMAC motors have a high-efficiency rating which means they can convert a large percentage of the electrical energy they consume into mechanical power. This makes them ideal for use in electric vehicles, where energy efficiency is a major concern.

High Power Density

PMAC motors are designed to be compact and lightweight, making them ideal for use in electric scooters and other small vehicles.

Low Maintenance

Unlike traditional DC motors, PMAC motors do not require regular maintenance, such as brush replacement.

High Reliability

PMAC motors are designed to be highly reliable, with long service life.

Permanent Magnet AC Motor Cons

High Cost

PMAC motors are typically more expensive than other types of electric motors, which can make them less attractive for certain applications.

Temperature Sensitivity

PMAC motors can be sensitive to temperature changes, which can affect their performance.

Complex Control Systems

PMAC motors require a more complex control system than other types of motors, which can make them more difficult to operate and maintain.

Limited Speed Range

PMAC motors are typically designed to operate at a single speed, which can make them less suitable for applications that require variable speed control.

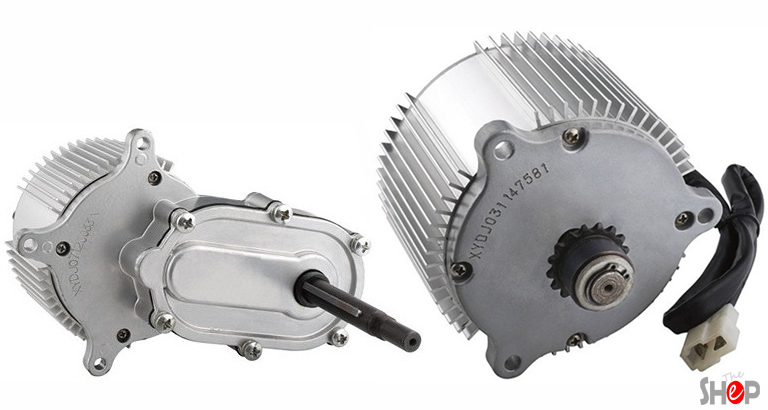

3. Hub Motors

An electric motor that is integrated into the wheel hub of a scooter is called a hub motor. This design eliminates the need for a drive train, chain, or gears, making it a compact and streamlined option.

Powering the motor is a rechargeable battery, and it can be controlled through a throttle or pedal-assist system. Within the hub motor category, there are two main types: direct drive and geared.

Direct drive hub motors possess higher torque output and are more efficient. However, they tend to be heavier and more costly in comparison. On the other hand, geared hub motors are less expensive but have a lower torque output and are less efficient.

Hub Motor Pros

Compact and Simple Design

The hub motor eliminates the need for a drive train, chain, or gears, making the electric scooter more lightweight and easy to maintain.

Easy to Install

Hub motors can be easily installed on almost any type of bicycle or scooter, making them a popular choice for conversions.

High Efficiency

Direct drive hub motors have a high torque output and are more efficient, which means they can provide more power and better range.

Low Maintenance

Hub motors do not require any maintenance or adjustments, making them a reliable option for long-term use.

Hub Motor Cons

High Cost

Hub motors, especially direct drive ones, are more expensive compared to other types of motors.

Limited Power

Geared hub motors have a lower torque output and are less efficient, which means they may not be suitable for high-performance or off-road use.

Limited Speed

Hub motors are designed to provide power at lower speeds, which makes them less suitable for high-speed applications.

Weight

Hub motors are heavier than geared ones, which may make them less suitable for lightweight electric scooters.

4. Direct Drive Motors

The direct drive motor is an advanced technology that uses high-performance magnetic materials and advanced control algorithms to achieve high power density, high efficiency, and low noise. It also features a high starting torque and a low-speed rotation, which makes it an ideal choice for electric scooters and other types of electric vehicles.

Direct Drive Motor Cons

High Efficiency

Direct drive motors are highly efficient, which means they require less energy to run, resulting in longer battery life and more range for your electric scooter.

Low Noise

Direct drive motors are much quieter than traditional geared motors, which is a big plus for electric scooters that are used in urban areas.

High Starting Torque

Direct drive motors can produce high starting torque, which means they can easily accelerate the vehicle from a standstill, making it easier to ride uphill or through challenging terrain.

Low Maintenance

Direct drive motors have fewer moving parts than geared motors, which means they require less maintenance and are less likely to break down.

Direct Drive Motor Cons

High Cost

Direct drive motors are more expensive than traditional geared motors, which can make them less accessible for some users.

Heavyweight

Direct drive motors tend to be heavier than geared motors which can make the electric scooter less portable and harder to carry around.

Limited Speed

Direct drive motors tend to have a limited top speed which means they may not be suitable for high-speed applications.

Limited Range

Direct drive motors tend to have a limited range.

Higher Power Requirement

Direct drive motors typically require a higher power source than geared motors which can make them less suitable for low-power applications.

Factors to Consider When Choosing an Electric Scooter Motor

Power and Torque

The power and torque of an electric scooter motor determine its acceleration and top speed. A higher power and torque motor will result in a faster and more powerful ride, but it will also consume more energy and may be more expensive.

Efficiency

The efficiency of an electric scooter motor is measured in terms of how much energy it converts into useful work. A more efficient motor will consume less energy, resulting in longer battery life and lower operating costs.

Cost

The cost of an electric scooter motor is an important factor to consider. The more powerful and efficient the motor, the more expensive it will be. It is important to balance the cost of the motor with the desired performance and battery life.

Durability

The durability of an electric scooter motor is a crucial factor to consider. A durable motor will last longer, reducing maintenance and replacement costs. It is important to research the durability of different types of motors before making a decision.

Final words:

Electric scooter motors play a crucial role in the performance and overall functionality of an electric scooter. In this article, we have described the different types of electric scooter motors available in the market, including Brushless DC Motors (BLDC), Permanent Magnet AC Motors (PMAC), Hub motors, and Direct Drive motors. Each motor type has its advantages and disadvantages, and it’s essential to consider factors such as power and torque, efficiency, cost, and durability when choosing the right motor for your electric scooter. Ultimately, the type of motor you choose will depend on your specific needs and preferences, but it’s essential to make an informed decision to ensure that your electric scooter performs at its best.

Frequently Asked Questions (FAQs)

- How long can an electric motor run continuously?

An electric scooter motor life ranges from less than two years to a decade, depending on various factors like usage and maintenance. Some motor manufacturers claim 30000 hours whereas others 40000 hours life of their e-scooter motors.

- Which motor is fast, DC or AC?

AC motors are more powerful than DC motors as they generate higher torque by utilizing a more powerful current. On the other hand, DC motors are more efficient and make better use of the input energy compared to AC motors.

- Which type of motor is best for an electric scooter?

Brushless DC motors are best for electric scooters with superior durability and better power to weight ratios. They also offer ultra-quiet operation and don’t overheat like other motors.

Arnold A. Jones: Your go-to source for electric scooters, hoverboards, and skateboards! Riding enthusiast and expert sharing tips, trends, and insights for riders of all levels. Stay in the know with Arnold’s expertise.

Leave a Reply